Product - HALO

Do CNC Machine Controls Really Need To Be So Complicated?

It’s hard to find experienced machinists. And when you do find one, they’re either over-worked and too busy—or work is slow and you’re trying to keep them occupied. What you really need is the flexibility to have almost anyone be able to setup & operate your CNC equipment. Wouldn’t it be great to have a control system that was so easy to use, your whole team could learn to run the machine in just a few hours—with no prior machining experience? If only your CNC control was as intuitive and easy-to-use.

Rapid Prototyping In-House Is Not A Pipedream

For many businesses, prototyping and part making seems out of reach because they have traditionally required specialized expertise, bulky and costly equipment, or both. Once you factor in the time and cost for training machinists, space for large equipment, and maintenance needs, you’re looking at a significant investment. Most companies end up out-sourcing or just skipping it altogether – even though they know that companies making their own prototypes or doing short-run production in-house have a distinct advantage over those who can’t. .

Simplify and Speed Up Complex Part Making

Machining complex, detailed parts on large, Large machining centers that were designed to manufacture a wide range of parts can be challenging. VMC’s use large cutting tools and have excessive size and weight that just isn’t needed for smaller tooling. In addition, traditional VMC’s require expertise that can be difficult to find and costly to employ. But what if you could make parts faster and easier with a system that was specifically designed for machining complex parts? What if you could reduce your entire part-making workflow exponentially? And what if it was so easy to use, nearly anyone could run it?

Machining Large Precision Parts Is Difficult and Can Be Costly to Produce

Some machining jobs leave very little room for error – and the larger the part, the greater the chance of not achieving a successful result. Repositioning parts because you don’t have the machining area can lead to errors, or worse. Working on existing parts that are already of high value is stressful and risky.

Transform Your Business, Reduce Rejected Parts, and Take the Stress out of Large Part, High-Tolerance Jobs

Minimize your risk, and your stress, by getting the job done right – the first time and is designed and built to the most exacting requirements and can improve your entire workflow.

Aerospace and Aviation

Prioritizing Customer Safety Means Making Precision Parts Right the First Time

For the past several decades, aerospace and defence manufacturers like to produce, You will wow your CMM department by making complex, intricate, precision parts with minimal to zero rejects by using this machine

Make Tight Tolerance Parts Once, and Improve Your Turn-Around Times

Are you looking for a high-speed machining system that meets your tight tolerances? Intricate and complex parts can be challenging with traditional machines. Heavy machines are designed for a broader range of applications, not for making small, detailed parts.HALO machines produce parts better, faster, and within your high tolerance demands. They also improve your overall machining efficiency with a streamlined workflow that minimizes set-up times, reduces cycle times, eliminates secondary ops – helping you get approval from your CMM department—the first time.

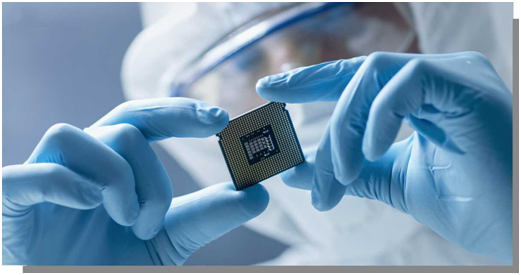

Consumer & Industrial Electronics Machining

Electromechanical Parts Requires Expertise

The semiconductor supply chain has never been so fragile, making this the ideal time to start manufacturing memory chips, microprocessors, standard chips, and SoCs domestically. HALO is ready to help you tap this growing market with HALO 5 axis simultaneous CNC machines that take you from prototype through production, right in-house. In fact, HALO machines are ideal for all types of consumer and industrial electronic applications and have helped major electronic brands produce everything from circuit boards and test fixtures, to electronic enclosures and heat sinks.

HALO Machines Are Versatile, Compact and Efficient.

Electronic manufacturers are challenged with finding versatile and compact systems that can efficiently prototype, produce, or repair intricate electronic-based mechanical parts. Traditional, large VMCs are messy, heavy, and require significant expertise to operate and maintain. Integrating one of those machines with your existing process is sometimes close to impossible. Unfortunately, having to outsource your project or wait in a queue for an in-house machining department to deliver your parts can cause delays. HALO CNC machines let you produce high-quality, precise electromechanical parts with the only compact, easy-to-operate, and clean machining systems that can be installed right in a laboratory.

Industrial Manufacturing

Speed Up Your Workflow to Lower Part Costs and Reduce Your Total Cost of Ownership

Why use a large, heavy system to make small, intricate parts? Compact industrial machines save you valuable floor space and use less electricity. The evaporative coolant requires zero maintenance with zero part clean-up, compared to messy oil-based coolant systems that incur disposal fees. And imagine the flexibility and cost-savings from having any of your shop employees be able to operate your equipment with a simple touch-screen control.

A Compact, Precise, Easy to Operate, Clean Machining System That You Can Install Right in Your Lab

With medical devices getting smaller and smaller the need to use small cutting tools is a high priority. To run those small tools efficiently, you need a high-speed milling machine that can effectively evacuate chips from the tool and cutting channel. That extends the life of cutting tools and produces a better-quality cut. Whether you’re manufacturing or prototyping, machining precision parts in your own environment is critical to your success. You can get all of that with a HALO machine that fits through a standard door and is virtually clean-room ready.

High-Speed Machining

Making Complex Parts Requires Speed and Precision at Every Stage of Your Process

Your customers need smaller and more complex parts every day. To meet this growing demand, you need 40,000-60,000 RPM spindle speeds and a workflow that supports them. But high-speed machining is about more than 60,000 RPM spindle-speed. You need to be able to set up, output, and change over to the next job faster. A LOT faster.High-speed machining means producing parts in minutes or hours instead of days. Discover first-hand why 60,000 RPM spindle speed is only one part of the story, and how We can help you optimize your entire high-speed machining workflow by requesting a live virtual demo or a site visit.